#1 Decorative Concrete & Surfaces Finishing Supplies

Best quality products with top customer service

You deserve your dream floor, don't settle.

Products for

EPOXIES, OVERLAYS, STAINS, SEALERS, TEXTURE MATS, TOOLS, ARTIFICIAL TURF AND MORE...

EPOXIES

Epoxy floors are durable and versatile coatings applied to concrete surfaces to provide a resilient and aesthetically pleasing layer. Comprising epoxy resins combined with hardeners, they create a solid surface that is easy to clean and resistant to stains, chemicals, and wear. Epoxy floors are popular in industrial, commercial, and residential settings due to their durability, modern appearance, and ability to enhance the resilience of existing surfaces. Moreover, they offer customizable design options, such as colors, textures, and patterns, making them a versatile choice for various applications.

DECORATIVE CONCRETE AND SEALERS

Decorative concrete is a form of aesthetic coating applied to concrete surfaces using techniques such as staining, stamping, or polishing to enhance its appearance. It is important to seal it to protect against wear, stains, and damage, thereby extending its durability and maintaining its aesthetic appeal.

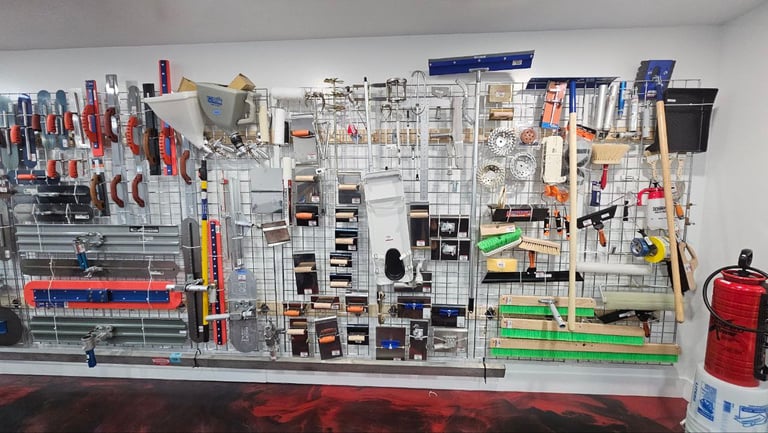

RENT AND SALES OF MACHINES AND TOOLS

We offer a wide range of high-quality tools and also provide rental services for specialized machines for concrete work.

Our Promotions

Turf Glue

1 GAL

Artificial turf

Adhesive

$416

$416

$384

$384

One box SEAM BINDER DC GREEN (1 gal x 8) 8 gal kit

Normaly is $52 /gl

(PROMO $48/ gl)

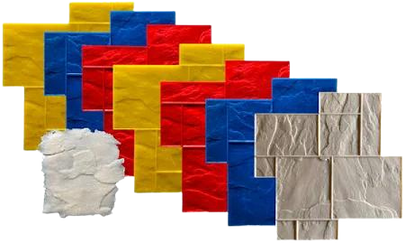

Texture Mats rent

$0

$100

$100

"If you make a purchase of $500 dollars in our products, the mold rental will be free for 1 day. If you purchase more than $50, the one-day mold rental would be $70. If you only rent the molds, it would be $100 per day."

$200

$200

PSI Fiberstrand

$150

"If you purchase a box of fiber (50 packages of 1/2 lb) or more, the price per package would decrease from $4 to $3, or $150 per box."

What We Can Offer You

"We are Global Stone Industries, South Florida's premier provider of Concrete Design Systems. We offer high-quality products, tools, training, and support to contractors and homeowners alike. Our extensive range of products includes Epoxies, Overlays, Stains, Sealers, Textured Mats, Tools, and more. Visit us for more information."

Artificial Turf

Tools and Machines

Products

Sealers

*SOLVENT BASE

INCRETE CLEAR SEAL - (5GL) & (1GL)

INCRETE PIGMENTED SEAL - (5GL) & (1GL)

*WATER BASE

URETHANE WATER BASED - 1 GLKIT

Overlay Systems

SPRAY DECK SINGLE COMP 50LB BG GRAY

SPRAY DECK SINGLE COMP 50LB BG WHITE

RENOVATE KIT (to fix stamp concrete)

* 35 Color can be added to the system; please refer to the color chart.

Colorants

Color Hardener 60 lb (PAIL)

*They come in 35 different colors. Please refer to the color chart.

INTEGRAL COLOR

*Thousands of colors available, custom colors can also be created.

RELEASE POWDER

*They come in 35 different colors. Please refer to the color chart.

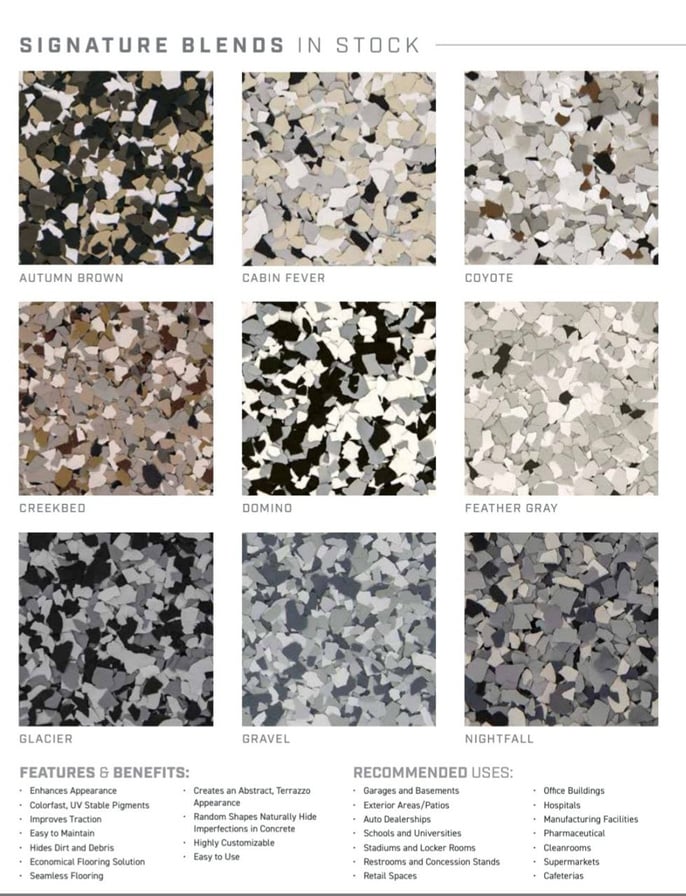

Epoxies

GS 100 (3 Gallon of Kit Epoxy System Solids Colors)

GS 100 ( 3 Gallon of Kit Epoxy System Clear )

Metallic Powder Pigment (5oz) G.Stone

Metallic Powder Pigment(12oz) G.Stone

Polyurethane Gloss Seamless Epoxy System

GS-P85 ( Clear Polyaspartic )

MVB ( Moisture Vapor Barrier )

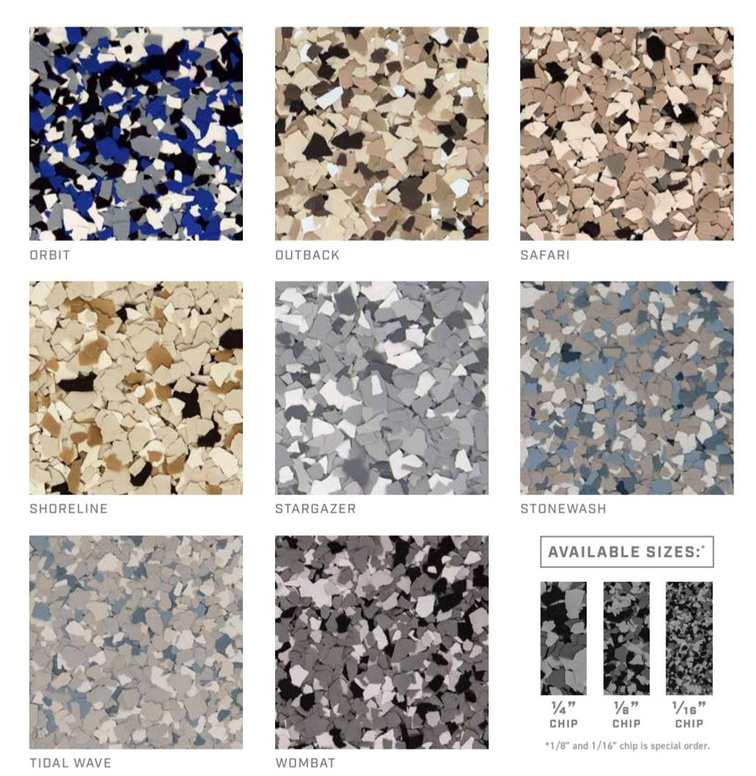

Flakes 1/4 (40lbs)

Flakes 1/4 (5lbs)

Chroma Quartz, 50 LB bag

Epoxy Tools (rollers, squeegees, spike shoes, etc)

Stains and Dyes

Stain-Crete ( acid stain ) 1gl

Stone essence ( water base stain ) 1 Qt

*available in 20 standard colors.. Please refer to the color chart.

Release Agents

RELEASE POWDER (35 lb pail)

RELEASE LIQUID

Pool Drains

White, Gray, Tan

-Deck drain 10' includes coupler and adapter-6.5 lbs (1.5'’ x 3'’)

-Deck drain 10' includes coupler and adapter-6.5 lbs (1.5'’ x 3') removable top

-Flowmaster 3 Deck Drain 10' (3'’x3'’) removable

-FLOWMASTER COMMERCIASL DRAIN 10' (4'’x 4'’)

* 3 colors availables:

*We sell all accessories, connectors, 90 degrees, T connectors, end caps, and end adapters.

Artificial Turf

-DIFERENTS BRANDS AND TYPES OF GRASS

(BLUEGRASS, ARIZONA PRO, NAVIGATION, ETC)

-TURF GLUE 1 GAL

-Galvanized Timber Tie Nails (30lb - Pack)

Aditives and Cleaners

Shur grip 1 lb

solvent 5 gl

solvent 1 gl

cobble strips 5 gl

PSI Fiberstrand 1/2 Lb or Box

Rentals & Tools

Tools

A wide variety of tools for working with concrete, epoxies, and much more. Brands like Bon, Kraft, Marshalltown...

Stamping Mats Rent

Grand Ashler Slate

ROYAL ASHLER SLATE

Ashler Slate

Bavarian Castle Stone

HERRINGBONE SLATE

Travertine Stone

Extra Large Random Stone

Flagstone

Wood Plank

Grand Ashler la habra

Reclaimed Timber Plank

Smoll Random Stone

Equipment Rental

We rent a variety of equipment to assist you in your projects.

Compactor Smoll

Compactor Large

Pro Grinder GENIE

Lines/Joints cutter machine

Artificial Turft Brush Power Broom

Generator

Hilti 14" Concrete Saw

Magna Trap Single Disc Floor Grinder

Hilti TE 3000 AVR Demolition Breaker Hammer with Cart

Pressure Cleaner

Data Sheets

Colorants

Stains and Dyes

Release Agents

Overlay Systems

Aditives and Cleaners

Sealers

Epoxies

Polyurethane Gloss Seamless Epoxy System

Color Chart

Sealers

Epoxies

Release Agents

Location

Business Hours

Business Hours

Monday to Friday

7:00 AM - 4:30 PM

Saturday

7:00 AM - 12:00 PM

Sunday

Closed

Monday to Friday

7:00 AM - 4:30 PM

Saturday

7:00 AM - 12:00 PM

Sunday

Closed

Phone

(786) 601-2459

orders@globalstoneindustries.com

Social

© All rights reserved Global Stone Corp

What Our Clients Say

Bought concrete tools here, and the quality is amazing. They're sturdy and made my projects a breeze. Customer service was also great in helping me pick the right ones.

Javier Ramos

They were a lifesaver helping me with the sealer application. Quick, friendly, and gave me all the tips I needed. Definitely coming back for more.

Lazaro Cordero

The prices offered by this company are unbeatable, especially considering the exceptional quality of their products. Initially, I had doubts about affordability, but I was pleasantly surprised.

Edgar Mendieta

GS 100

REGULAR setting epoxy coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

PRODUCT DESCRIPTION

COLORS

GS 100 is a two-component epoxy coating containing 100% solids (solvent-free), no VOCs and virtually odorless materials. The product has excellent resistance to UV rays and the tendency to yellowing over time is one of the slowest in the industry. In addition, GS 100 has superior mechanical and chemical properties, making it an ideal choice for residential and commercial applications. The product provides a very long working time and pot life, which facilitates its application. It was formulated to be used as a topcoat but can also be used as a basecoat. The GS 100 is self-prime thus, no need for an additional primer. The formulation of GS 100 is based on the most recent technological

advances in cycloaliphatic polyamines providing excellent properties and

an impeccable aesthetic finish.

ADVANTAGES:

Essentially odorless Self-Priming

VOC Compliant High Color stability

High Sheen Chemical resistance

Potential for LEED eligibility Seamless Coating

Withstands average traffic at a minimum thickness of 8Mils

System offering the best UV resistance in the industry

Environmentally friendly, 100% solids, VOC and solvent free

Ease of application with long pot life and long working time

Excellent elongation and abrasion resistance

High resistance to the phenomenon of rising amine and contaminants (fish eyes).

Superior mechanical and chemical properties

Impermeability / Mold resistant

High density of the product preventing the penetration of dirt and facilitating maintenance

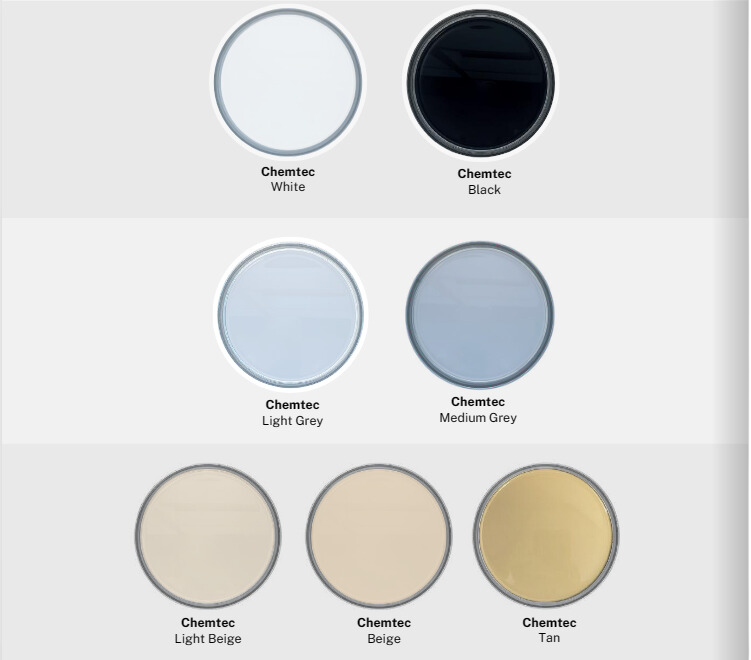

CHEM100™ is available in several standard colors, custom colors, liquid pigments, metallic pigments, and clear. (See the GS ™ color chart)

By diffusing colored flakes, colored quartz or silica sand, endless

combinations of colors and textures can be created.

(* additional charges may apply)

Available colors:

• Standard Colors • Liquid Pigments

• Metallic Pigments

• Red Tile* • Red Security*

• Blue Security* • Yellow Security*

• Green Security *

PACKAGING

The GS 100 kit consists of Resin Part A and Part B Hardener.

Part A Part B

Unit of 1 gallon Pre-Mesured Pre-Mesured

3 Gallon Kit 2 Gallons 1 Gallon

15 Gallon Kit 10 Gallons 5 Gallons

Barrel Kit 104 Gallons 52 Gallons

TESTING

All surfaces are not the same. It is recommended to create a sample

area before starting the project. The test should be performed on site,

using the method offered by your Global Stone representative to ensure

good adhesion and color. A sampling area should also be performed on

existing coatings to determine if there are any contaminants or if

delamination will occur.

APPLICATIONS

• Pharmaceuticals

• Garage floors

• Kitchens

• Corridors

• Showrooms

• Laboratories

• Commercial Centers

• Office buildings

• Food processing

• Washrooms & Showers

• Manufactures/Fabrication

• White Rooms

• Schools

• Hospitals

• Retail Stores

• Warehouses

PHYSICAL PROPERTIES

PROPERTIES

Compressive Strength Flexural Strength:

Tensile Strength:

Bond Strength (concrete):

Taber Abrasion:

Flammability

Hardness(Shore D):

Water Absorption:

Impact Resistance

Flash Point:

Abrasion Resistance

(CS-17 Wheel, 1,000 g load, 1,000 cycles)

VALUES

REFERENCES

14,000 psi – 96MPa ASTM C 579 3,700 psi – 25.5MPa ASTM D 790 3,900 psi – 26.9MPa ASTM D 638 350psi – (2.4) ASTM D 4541

Concrete fails at this point

75-80 Mgs ASTM D 4060 Self-extinguisher ASTM D 635

85 ASTM D 2240

< 0.1% ASTM D 570

< 0.1% MIL D 3134 No chipping, cracking,

ASTM D 2240

or delaminating

>200°F - >93°C

0.150 mg loss ASTM D 4060

www.globalstoneindustries.com

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION 2.3 : JUNE 2023 0

10810 SW 188th ST, Cutler Bay, FL 33157, US

GS 100

REGULAR setting epoxy coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

PRODUCT DATA

Volumetric Ratio:

Solids Content:

*Coverage:

Application Temperature:

Min Substrate Temperature: Max Substrate Temperature: Thinner:

Pot Life @ 21ºC:

**Drying / Curing Time : Working Time:

Tack Free:

Pedestrian:

Traffic:

Curing Time @ 21ºC for

resurfacing:

Shelf Life:

USDA Food & Beverage & CFIA:

2:1

100%

75 - 600 P.C.

65-90°F (18-32°C)

50oF (10oC)

86oF (30oC)

Not required

15-20 minutes

30-40 minutes

12 hours

24 hours

48 hours

24 hours

12 months

Meets the requirements

*Coverage will differ depending on the quality, porosity, of the substrate, thickness, and application methods.

**Based at 71F (22C) & 55% relative humidity

CHEMICAL RESISTANCE

REAGENT

RESULTS

ASTM 1308, Covered 7 days.

Detergent solution (5% Ajax) Unaltered

Sodium Chloride 20%, Unaltered

Calcium Chloride 20% Unaltered

Ammonia 20% Unaltered

Trisodium phosphate 20% Unaltered

Caustic Soda 20% Unaltered

Javex 3% Unaltered

Mineral spirits Unaltered

Methanol Unaltered

Toluene Unaltered

Xylene Unaltered

Hydrochloric acid 10% Unaltered

Citric acid 10% Unaltered

Lactic acid 5% Unaltered

Unleaded petrol Unaltered

Coffee Unaltered

Tea Unaltered

Beer Unaltered

Skydrol Unaltered

Nitric acid 10% Some yellowing

Sulfuric acid 10% Slightly discolored

PREPARATION OF CONCRETE

Before applying the coating, the concrete must be:

Dry – No wet zones (<4%)

Clean – Eliminate all contaminants, dust, grease, coatings,

delaminated coatings, laitance, or any other contaminants that

may affect and/or decrease or prevent a good adhesion.

Profiled – Machanically profilled surface at a CSP2-6

Sound – All cracks and shelled areas must be repaired.

Concrete preparation must be done by mechanical means, or any

other method approved by Global Stone

Mechanical preparation is the preferred method of preparing

concrete for coating application. Shot-blasting, diamond grinding,

scarifying and scabbling are all acceptable methods. Contact your

Global Stone Representative for suitable preparation method.

PATCHING & REPAIRS

Cavities, cracks, joints, and imperfections will be visible in the coating if the concrete is not repaired properly. Level and fill the concrete

cavities with GS-FILLER™ or GS-FILLER FC™. Once the material is cured, correct any imperfections by diamond sanding. If a repair material other than GS™ is used, contact a GS™ technical representative for approval of a compatible alternative.

MIXING

The ratio GS 100 is 2 to 1. That is, two parts A (resin) to one part B (hardener). Generally, three mixed gallons of GS 100 at a time is ideal for application. Mix the following with a drill and mixing paddle. Note: If using a drill mixer, use a low speed (not to exceed 300 rpm) to prevent air entrapment.

1. Add 1 gallon of GS 100 Part B into the premixed 2 gallons of

Part A and mix for another 3 minutes.

2. GS 100 is designed to be immediately poured on the floor.

Leaving mixed product in the container will greatly reduce working

time. Once poured out on the floor, 30-40 minutes of working time

can generally be expected.

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION 2.3 : JUNE 2023 0

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

GS 100

REGULAR setting epoxy coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

APPLICATION INSTRUCTIONS

Application of GS 100 for a solid color coat system is applied in two coats or in one pass as a topcoat over GS 100. For estimation

purposes, use from 25 SF (colored) to 200 SF per gallon in either case.

1. Always apply in descending temperatures. Concrete is porous and traps

air. In ascending temperatures (generally mornings) the air expands

and can cause out gassing in the coating. It is safer to apply coatings in

the late afternoon, especially for exterior applications.

2. Optimum ambient temperature should be between 65-90°F during

application.

3. Mix three gallons of resin using above mixing instructions.

4. Apply approximately 25 SF (colored) to 200 SF per gallon by

immediately pouring out on surface in a ribbon, while walking and

pouring at the same time until bucket is empty.

5. Using a squeegee on a pole, pull GS 100 over substrate. As a first

coat over bare concrete, pull resin as thin as possible while still wetting

out concrete and uniformly covering surface. This allows trapped air to

escape more easily. To apply in a single coat over a GS 100, pull at

about 150-200 SF per gallon.

6. Using a 10MM non-shedding roller, roll coating forwards and

backwards.

7. Lastly, back roll in the opposite direction as step 6.8. Apply second coat

by repeating steps 1-7 the next day.

8. Sweep floor and sand any high spots or defects.

9. Apply Top-Coat at approximately 125 S/F per gallon. Use the same

procedure as in Step 4, but without broadcasting.

10. For a 100-125 mil double broadcast system, repeat above steps.

*If additional chemical and abrasion protection is required, contact

your Global Stone representative for recommendations.

Chip/Silica Sand Broadcast Instructions

1. Chip Broadcast: After Following Steps 1-4 from Quartz broadcast, Next

Broadcast Color Chips/Micro Chips (150-200 SF per 25 lb. box) by

tossing them into the air and allowing them to gently rain down into

the wet resin.

2. For a random broadcast, use 1 lb. of chips per 100 S/F.

3. Allow to cure. Then scrape the basecoat with a drywall scraper in all

directions. Or lightly sand chips using a floor maintainer machine.

(sanding will result in smoother finish) Vacuum small pieces and dust

well. (Not vacuuming well enough can cause coating to not bond

correctly.)

4. Silica Sand Broadcast: Following Step 6 above, gently throw the silica

sand up into the air, allowing it to fall without lumping in one spot or

moving the resin. Do this until the floor is totally saturated with the

silica sand and the resin will not accept any more. This generally

requires 1/2 to 3/4 lbs. per S/F. Allow to dry for 4-6 hours.

5. Sweep floor and sand any high spots.

6. Following either method, apply final topcoat GS 100 SERIES,

GS-P85 & GS-P85 WT Polyaspartic, or GLOSS FINISH

Polyurethane Coatings.

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION 2.3 : JUNE 2023 0

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

GS 100

REGULAR setting epoxy coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

PRODUCT LIMITATIONS

SAFETY DISCLAIMER

Concrete slabs at ground level emit invisible moisture vapor. The permissible moisture emissions for concrete are 3 lb. / 1000 CP over 24 hours (<4%) based on calcium chloride test. In addition, a relative humidity (RH) test can be performed to test for moisture vapor. Relative humidity test results should be less than 85% per ASTM F2170. If humidity is above this level, blistering and delamination of the coating may occur. A calcium chloride or relative humidity test should be performed to determine the moisture levels of the concrete. If humidity levels exceed 85% for RH test or 3 lbs. for calcium chloride, a concrete moisture vapor control system

should be used before applying the coating system.

MVB System is the recommended system for humidity above

acceptable levels. The MVB vapor barrier system Passes the

F3010 specification based on E96 test results. Please contact your

Global Stone representative for details.

Coating systems are susceptible to cracking if the concrete moves or

separates under the coating. Therefore, the treatment of joints and cracks

should be reviewed prior to coating application. As a general rule, control

joints (saw cuts) and random cracks should first be sawn or chiseled and

then filled with GS-FILLER™ or GS-FILLER FC™. Construction / cold

joints (two slabs that meet and therefore move) must be treated. After the

coating has been applied and cured, saw off the coating over the

construction joints and apply elastomeric caulk.

Avoid contact with the skin. Some people may be allergic to the resin. Protective gloves, adequate ventilation and protective eyewear and protective clothing are recommended.

For more details, consult the GS 100 “Material Safety Data Sheet”.

– KEEP OUT OF REACH OF CHILDREN - FOR INDUSTRIAL USE ONLY -

–

The information presented herein are believed to be accurate and reliable but are presented without guaranties or responsibility on the part of GLOBAL STONE COATINGS™. It is the responsibility of the end user to verify and validate this information and the suitability of this product in their own systems. GLOBAL STONE COATINGS™. decline all responsibility for the use of this product in any systems.

WARRANTY

GLOBAL STONE coatings products are guaranteed for one year from the date of application. Please refer to the GLOBAL STONE COATINGS Limited Warranty for additional information.

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION 2.3 : JUNE 2023 0

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

GS-P85

High performance Polyaspartic coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

PRODUCT DESCRIPTION

GS-P85 is a two-component (1:1) Polyaspartic coating system.

The GS-P85 is used as a basecoat (colored) and a clear topcoat using a common hardener. It provides a quick turnaround with very rapid curing time (tack free of approx. 180 minutes) under normal conditions allowing the installation of a flooring system in a single day. This product offers superior mechanical and chemical properties and is low maintenance. It also displays a superior aesthetic finish and complete UV stability. If needed, we recommend the utilization of the Global Stone vinyl chips/Quartz/Aggregates in combination with GS-P85 products.

(Ask a Global Stone representative for additional details).

COLORS

Available in clear and colored (See the GS™ color chart)

Endless color and texture combinations can be achieved by dispersing

colorful flakes, colored quartz, or silica sand.

Available colors:

• Standard Colors • PolyBase (Liquid Pigments)

• Red Security* • Blue Security*

• Green Security * • Yellow Security*

(* additional charges may apply)

ADVANTAGES:

Indistinct odor

VOC Compliant

High Sheen

Potential for LEED eligibility

Low maintenance Environmentally friendly, 100% solids, VOC and solvent free Excellent elongation and abrasion resistance

Superior mechanical and chemical properties

WT version offers longer working time.

Self-Priming

High Color stability

Chemical resistance

Seamless Coating

Aliphatic

Multi-Coat application in one single day.

Impermeability / Mold resistant VOC and EPA Compliant in all States and Canadian Provinces CIFA, USDA, FDA, Food Safety Compliant

APPLICATIONS

The chemical and mechanical properties of GS-P85 provide excellent results for several ap provide excellent results for several applications.plications.

• Pharmaceuticals • Food processing

• Garage floors • Washrooms & Showers

• Kitchens • Manufactures/Fabrication

• Corridors • Public facilities

• Showrooms • Schools

• Laboratories • Hospitals

• Commercial Centers • Retail Stores

• Office buildings • Warehouses

• Other Residential applications • Other commercial applications

PACKAGING

The GS-P85 kit consists of Resin Part A and Part B Hardener.

Part A Part B

2 Gallon Kit 1 Gallons 1 Gallon

10 Gallon Kit 5 Gallons 5 Gallons

Larger units available upon request

TESTING

All surfaces are not the same. It is recommended to create a sample

area before starting the project. The test should be performed on site,

using the method offered by your Global Stone representative to ensure

good adhesion and color. A sampling area should also be performed on

existing coatings to determine if there are any contaminants or if

delamination will occur.

CHECK CONCRETE MOISTURE

Concrete must be dry before application of this floor coating material. Concrete moisture tests are required, either ASTM F1869 (calcium chloride) or ASTM F2170 (in situ RH probe) or any other methods approved by GLOBAL STONE CORP.

CHECK TEMPERATURE AND HUMIDITY

Floor and material temperature must be at or above the published Technical Data Sheet requirements. Dew point must be 5°F (3°C) or more below the surface temperature. Do not apply if humidity is at or above 85%.

SURFACE PREPARATION

Surface preparation in accordance with: ICRI Guideline No. 310.2R Selecting and Specifying Concrete Surface Preparation for Sealers, Coatings, Polymer Overlays, and Concrete Repair. The pH of the concrete substrate should be at 9 or above. All bond-breaking material must be removed.

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

GS-P85

High performance Polyaspartic coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

PHYSICAL PROPERTIES

PROPERTIES

Compressive Strength Flexural Strength:

Tensile Strength:

Bond Strength (concrete):

Flammability

Hardness(Shore D):

Water Absorption:

Impact Resistance

Flash Point:

Abrasion Resistance

(CS-17 Wheel, 1,000 g load, 1,000 cycles)

VALUES

REFERENCES

14,000 psi – 96MPa ASTM C 579 3,700 psi – 25.5MPa ASTM D 790 8,000 psi – 55.2MPa ASTM D 638 350psi – (2.4) ASTM D 4541

Concrete fails at this point

Self-extinguisher ASTM D 635

>65 ASTM D 2240

< 0.1% ASTM D 570

< 0.1% MIL D 3134 No chipping, cracking,

ASTM D 2240

or delaminating

>200°F - >93°C

58 mg loss ASTM D 4060

PRODUCT DATA

Volumetric Ratio:

Solids Content:

*Coverage (Wet Mils): **Application Temperature: Min Substrate Temperature: Thinner:

Pot Life @ 21ºC:

**Drying / Curing Time : Working Time:

Tack Free:

Light Foot Traffic:

Traffic:

Max Curing Tim for resurfacing: Shelf Life:

USDA Food & Beverage & CFIA:

1A:1B

85%

150 - 200 SQ. FT.

50-90°F (10-32°C)

33oF (1oC)

Not required

10-15 minutes

25 minutes

2 hours

5-7 hours

24 hours

24 hours

12 months

Meets the requirements

*Coverage will differ depending on the quality, porosity, of the substrate, thickness, and application methods.

**Based at 71.6oF (22oC) & 55% relative humidity.

Higher temperatures and humidity will shorten pot-life and working time.

CHEMICAL RESISTANCE

REAGENT

RESULTS

ASTM 1308, Covered 7 days.

Skydrol Unaltered

Betadine Unaltered

Calcium Chloride 20% Unaltered

Ammonia 20% Unaltered

Trisodium phosphate 20% Unaltered

Caustic Soda 20% Unaltered

Javex 3% Unaltered

Mineral spirits Unaltered

Methanol Unaltered

Toluene Unaltered

Xylene Unaltered

Hydrochloric acid 10% Unaltered

Citric acid 10% Unaltered

Lactic acid 5% Unaltered

Unleaded petrol Unaltered

Coffee Unaltered

Tea Unaltered

Beer Unaltered

Skydrol Unaltered

Nitric acid 10% Some yellowing

Sulfuric acid 10% Slighly discolored

CONCRETE SURFACE PREPARATION

Before applying the coating system, the concrete must be:

Dry – No wet zones (<4%)

Clean – Eliminate all contaminants, dust, grease, delaminated

coating, laitance, or any other contaminants that may prevent proper

adhesion.

Profiled – Mechanically profiled Surface (Surface Preparation ICRI

Guideline No. 310.2R Concrete Surface Profile (CSP 2 and above)

Depending on System to be Installed and Condition of Concrete,

and/or approved by a Global Stone Representative.

Sound – All cracks and chipped areas should be repaired with GS-

FILLER™, GS3000™.

Concrete preparation must be carried out by mechanical means such

as shot blasting, grinding, sandblasting, or any other method

approved by GLOBAL STONE

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

GS-P85

High performance Polyaspartic coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

PATCHING & REPAIRS

Cavities, cracks, and imperfections will be visible in the coating if the

concrete is not repaired properly. Level and fill the concrete cavities with

GS3000™, GS-FILLER™, or GS-FILLER FC™. Once the material is

cured, correct any imperfections by diamond sanding. If a repair material

other than GS is used, contact a Global Stone technical

representative for approval of a compatible alternative.

MIXING

The mixing ratio for the GS-P85 is 1 for 1 (by volume). In other words, one parts A (resin) for one part B (hardener).

Mix the GS-P85 using a drill and a mixing paddle.

Note: If using a drill mixer, use a low speed (not to exceed 300 RPM) to avoid air entrapment.

1. Add the contents of the pre-measured GS-P85 and mix for 2

minutes.

2. GS-P85 is designed to be immediately poured onto the floor.

Leaving the mixed product in the container will greatly reduce the

working time. Once unloaded on the ground, you can usually expect

**15 minutes of working time @ 22oC (71.6 oF).

APPLICATION INSTRUCTIONS

The application of the GS-P85 for a solid color coating system is applied in two coats or in a single pass as a topcoat. For estimation

purposes, estimate between 75-200ft2 per gallon in both cases.

1. Always apply at decreasing temperatures. Concrete is porous and traps

air. At rising temperatures (usually in the morning), the air expands and

can cause gas to escape in the coating. It is safer to apply the coatings

in the late afternoon, especially for exterior applications.

2. The optimum ambient temperature should be between 18 and 32oC

(65 & 90°F) during application.

3. Mix the gallons of resin using the mixing instructions above.

4. Apply approximately 75-100 ft2 per gallon while immediately pouring

on the surface in a ribbon pattern, while walking and pouring at the

same time until the bucket is empty.

5. Using a squeegee on an extension, pull the GS-P85 over the

substrate. As the first coat over bare concrete, pull the resin as thinly as

possible while wetting the concrete and evenly covering the surface.

This allows the trapped air to escape more easily. To apply in a single

coat over a GS-P85 pull at approximately 75-100ft2 per gallon.

APPLICATION INSTRUCTIONS (CONTINUED)

6. Using a 10mm microfiber roller, roll evenly forward and backward. 7. Finally, back up in the opposite direction in step 6.

8. Clean & sweep the floor and sand any high points or imperfections. 9. Apply topcoat at approximately 100 sq. ft. per gallon.

Use the same procedure as in step 4.

10. If additional chemical, abrasion, and/or anti-slip protection is

required, contact your Global Stone representative for

recommendations.

Decorative Colored Flakes Diffusion

System Instructions

1. Decorative Flakes Diffusion: After following the basecoat

application in steps 1-4, then diffuse the color flakes (120-200ft2

per 25 lb box) by tossing them in the air and allowing them to rain

gently in the wet resin.

2. For random / partial broadcast, use 1 lb of flakes per 100ft2.

3. Leave to dry. Then scrape the basecoat with a drywall scraper in all

directions. Or lightly sand the chips using a ground holding

machine. (sanding will give a smoother finish) Vacuum small pieces

and dust well.

(Not enough vacuuming can lead to poor adhesion of the coating).

Decorative Colored Quartz & Silica Sand Diffusion System Instructions

1.

2.

3.

4.

Quartz & Silica Sand Diffusion: Following step 6 above, gently toss the aggregates into the air, allowing it to fall without clumping in one place or moving the resin. Do this until the resin is completely saturated with silica sand/Quartz and the resin can no longer be filled. This usually requires 1/2 to 3/4 lb. by square feet.

Let dry for 4-6 hours.

Clean and sweep the floor and sand any high points.

Finishing: Apply the topcoat GS-P85 following steps 1-6. If additional chemical, abrasion, and/or anti-slip protection is

required, contact your Global Stone representative for

recommendations.

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

GS-P85

High performance Polyaspartic coating

Technical Data Sheet

COMMERCIAL INDUSTRIAL INSTITUTIONAL RESIDENTIAL

PRODUCT LIMITATIONS

Concrete slabs at ground level emit invisible moisture vapor.

The permissible moisture emissions for concrete are 3 lb. / 1000ft2 over 24 hours (<4%) based on calcium chloride test. Additionally, a relative humidity (RH) test can be performed to test for moisture vapor. Relative humidity test results should be less than 85% per ASTM F2170. If humidity is above this level, blistering and delamination of the coating may occur.

A calcium chloride or relative humidity test should be performed to determine the moisture levels of the concrete. If humidity levels exceed 85% for RH test or 3 lbs. for calcium chloride, a concrete moisture vapor control system should be used before applying the coating system.

System recommended for cases of humidity above acceptable levels;

MVP Vapor Barriers passes the F3010 specification based on E96 test

results. Please contact a Global Stone representative for details.

Coating systems are susceptible to cracking if the concrete moves or

separates under the coating. Therefore, the treatment of joints and

cracks

should be reviewed prior to coating application. As a general rule, control

joints (saw cuts) and random cracks should first be sawn or chiseled

and

then filled with GS-FILLER™ or GS-FILLER FC™, or GS3000™.

Construction / cold joints (two slabs that meet and therefore move)

must

be treated. Once the coating has been applied and cured, saw off the

coating over the construction joints and apply elastomeric joint filler.

WARRANTY

GLOBAL STONE CORP. products are guaranteed for one year from the date of application. Please refer to the Global Stone Hardware Limited Warranty for additional details.

DISPOSAL

Excess material (A and B) should be mixed and allowed to cure.

Cured product may be disposed without restriction.

Uncured materials should be stored in a suitable and sealed container

and may be disposed in accordance with provincial, State, municipal,

and /or Federal regulations.

SAFETY WARNING

Avoid contact with the skin. Some people may be allergic to epoxy

resin. Protective gloves, eyewear, protective clothing, and adequate ventilation are recommended.

For additional information and advice on the safe handling, storage and

disposal of chemical products, users should refer to the most recent

GS-P85 Material Safety Data Sheet containing physical,

ecological, toxicological, and other safety-related data.

– KEEP OUT OF REACH OF CHILDREN –

- FOR INDUSTRIAL USE ONLY -

– KEEP FROM FREEZING –

The information presented is, we believe, accurate and in compliance; however, it is provided with all reservations and without warranties from GLOBAL STONE CORP. Therefore, it is the user's responsibility to thoroughly verify and validate this information, as well as the suitability of this product for the intended use. GLOBAL STONE CORP will not be held liable for the use of this product in any systems.

The Information, and in particular, the recommendations relating to the

application and end-use of GLOBAL STONE COATINGS products, are given

in good faith based on GLOBAL STONE CORP current knowledge and

experience of the products when properly stored, handled, and applied under

normal conditions, within their shelf-life.

In practice, the differences in materials,

substrates and actual site conditions are such that no warranty in respect of

merchantability or of fitness for a particular purpose, nor any liability

arising out of any legal relationship whatsoever, can be inferred either from

this information, or from any recommendations, or from any other advice

offered. The information contained herein does not relieve the user of the

products from testing them for the intended application and purpose. The

proprietary rights of third parties must be observed. All orders are accepted

subject to our current terms of sale and delivery. Users must always refer

to the most recent issue of the local product Technical Data Sheet for the

product concerned, copies of which will be supplied on request or may be

downloaded from our website at: www.globalstoneindustries.com

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

/

MVB

Epoxy Moisture Mitigation Primer System

TECHNICAL DATA SHEET Section 03 01 37

EditionV.2.2 09/2022

PRODUCT DESCRIPTION

PHYSICAL PROPERTIES

As a primer on substrates with high residual moisture

- Up to 10 wt.-% on concrete

- Up to 6 wt.-% on heated concrete (kiln drying testing necessary)

- Up to 5 CM-% on unheated cement screed

- Up to 3 CM-% on cement screed with floor heating

- Up to 0,8 CM-% on unheated calcium sulphate screeds

- Up to 0,5 CM-% on calcium sulphate screeds with floor heating

As a primer to improve adhesion on smooth and sound substrates As a protective membrane against moisture out of auxiliary

products by substrates sensitive to moisture

MVB is 4:1, 100% solids, 0 VOC, two-component epoxy resin- based primer based on phenolic amine chemistry specifically designed as a moisture barrier for concrete floors with very high residual

moisture prior to laying floor coverings, coatings, or parquet.

(Up to 22 lbs/1000ft2/24 hr.).

MVB is Also suitable on calcium sulphate-based screeds with

slightly higher residual moisture.

As a primer for absorbent, non-absorbent as well as smooth surfaces.

For interior and exterior use.

Concrete slabs at ground level emit invisible moisture vapor. The

permissible moisture emissions for concrete are 3 lb./1000ft2 over 24

hours (<4%) based on calcium chloride test. In addition, a relative

humidity (RH) test can be performed to test for moisture vapor.

Relative humidity test results should be less than 85% per ASTM F2170.

If humidity is above this level, blistering and delamination of the coating

may occur. A calcium chloride or relative humidity test should be

performed to determine the moisture levels of the concrete. If humidity

levels exceed 85% for RH test or 3 lbs. for calcium chloride, the

MVB concrete moisture vapor control system is designed to

be used before applying the coating system.

Vapor Permeance @ 18mils thickness ≤ 0.1% perm. ASTM E96 MVER/RH @ 18 mil thickness up to 22 lb./24 hr./1000ft2 ASTM F1869

PACKAGING

CARACTERISTICS

Made from 100% solids

Resistant to chemical loadings

Good penetration

Can be applied to almost all substrates

Grip promoting

Suitable for application on subfloor heating systems

Resistant to bacteria and moisture Exceeds ASTM F3010 standards

0 VOC

Suitable on damp substrates High sealing function

For increased residual moisture and single-layer application Magnesite screeds

Old sealed/coated surfaces Impermeable and seamless.

Up to 22 lbs/1000ft2/24 hr.

TYPICAL USES

Where the concrete moisture content exceeds 4% or, 3 lb./1000ft2

over 24 hours.

TESTING

All surfaces are not the same. It is recommended that a sample area be done before the start of the project. A sample area should also be done on any existing coatings and/or substrate to determine if any contaminants exist or if delaminating will occur.

The MVB kit consists of Resin Part A and Part B Hardener.

Part A Part B

2.5 Gallon Kit 7.56 Liters 1.89 Liters

Volumetric Ratio:

Solids Content:

*Coverage:

Application Temperature:

Min Substrate Temperature: Max Substrate Temperature: Thinner:

Pot Life @ 21ºC:

**Drying / Curing Time : Working Time:

Tack Free:

Pedestrian:

Traffic:

Curing Time @ 21ºC for resurfacing:

Shelf Life:

USDA Food & Beverage & CFIA:

LEED V4.

4A:1B

100%

90 ft2/Gallon – 222 ft2 Kit 32-90°F (0-32°C)

32oF (0oC)

86oF (30oC)

Not required

5 minutes

@ 21oC (70oF)

15 minutes

4-6 hours

12 hours

24 hours

24 hours

12 months

Meets the requirements Compliant

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

/

MVB

Epoxy Moisture Mitigation Primer System

TECHNICAL DATA SHEET Section 03 01 37

EditionV.2.2 09/2022

PROPERTIES

Property

Compressive Strength:

Flexural Strength:

Tensile Strength:

Bond to concrete:

Taber Abrasion:

Flammability

Hardness, Shore D

Flash Point:

Value Reference

11,000 psi ASTM C695

13,900 psi ASTM D790

9,000 psi ASTM D638

450 psi ASTM D4541

Concrete fails at this point

75-80 Mgs ASTM D4060

Self-Extinguishing ASTM D635

84 ASTM D2240

>200oF (93oC) ASTM D93

As used as a moisture barrier all swellable respectively not water- resistant layers must be removed completely.

Old floors, such as ceramic tiles are to be thoroughly cleaned and

sanded.

Unheated concrete substrates must be at least 6 weeks old.

Heated concrete substrates must be at least 3 months old and

have been already heated up.

Concrete substrates may be present wettish, but free of puddles.

Smooth and tight concrete substrates should be prepared of with

a coarse surface (e.g., grit-blasting or milling).

The requirements of the relevant valid standards, guidelines and

data sheets apply.

MVB @ 20MILS THICKNESS

SUITABLE SUBSTRATES

Concrete

Cement and rapid cement screeds

Calcium sulphate-based screeds.

Old substrates such as ceramic tiles, natural stones, and terrazzo Magnesite screeds

RECOMMENDED USES

APPLICATION & CONSUMPTION

ROLLER APPLICATION 1ST LAYER:

ADDITIONAL LAYER:

Concrete Surfaces Decorative Chips/Flakes Decorative Quartz

Metallic Coating System High/Thin Build Systems Mortars

Cementitious Overlays Polymeric Flooring

Approx. 300 g/m2 (7.12 lb/ft²) > 23.56ft²/L

Approx. 200 g/m2 (4.75 lb/ft²)

QUARZSAND (0.2 – 0.8 mm)

approx. 3-4 kg/m2 (71-95 lb/ ft²)

Toothed trowel application (single-layer, toothing TKB B2)

Approx. 500 g/m2 (11.87 lb/ft²).

The applied quantity varies depending on roughness depth and

porosity of the subfloor and differs depending on material, and

subfloor temperature as well as the applicator.

Low temperatures raise viscosity and therefore material

consumption.

• Clean – Free of any contaminants, grease, oil, paint, curing agents,

dust, loose coating, and laitance removed or any other

contaminants that may prevent proper adhesion.

• Profiled – Mechanically prepared to obtain a CSP2-4

REQUIREMENTS OF SUBSTRATE

Adequate dryness, strength, bearing strength, evenness, and dimensional stability.

Recommended maximum level of residual moisture should not be

exceeded.

Free of residues which reduce adhesion, e.g., dust, dirt, oil, and

loose particles.

Separation layers, sinter layers, and other similar contamination

should be removed through appropriate measures, such as

sanding, brushing, abrasive blast cleaning, milling or thorough

cleaning.

Old adhesive residues and levelling layers with no sufficient

hardness should be removed completely by suitable mechanical

means.

Layers of water-soluble adhesives, e.g., sulphite-waste-adhesives,

are to be mechanically removed.

Old water-resistant adhesives are to be mechanically removed as

far as possible.

WWW

.EPOXYCHEMTEC.

COM

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

/

MVB

Epoxy Moisture Mitigation Primer System

TECHNICAL DATA SHEET Section 03 01 37

EditionV.2.2 09/2022

STORAGE

RECOMMENDED METHOD OF APPLICATION

General

Thoroughly mix the MVB resin component by volume

(4:A) with the MVB hardener component (1:B) until

the material is homogenous and free of streaks.

Thoroughly mixing the combined parts using a Drill mixer and

Heli-mixing paddle for 3 (three) minutes.

Repot the mixed material and mix shortly again.

Small amounts can be mixed according to volume stated.

Material is immediately ready for use after mixing base and

activator together; no induction time is required. Do not mix

more material than can be used within the working time.

Material that has begun to set (thicken) cannot be satisfactorily

used and must be discarded.

Apply the MVB coat with flat or notched squeegee

with EPDM rubber blade and a 10mm microfiber roller evenly on

the clean substrate in cross coat. Spread material to uniform

thickness.

The second coat is applied after appropriate drying time of the

first coat.

For two-layer application take care of a minimum consumption of

500 g/m2 (11.87 lb/ft²)

In the fresh phase of the material sand in excess with clean, dry QUARZSAND (0,2-0,8 mm). Put forward only as much surface as can be sanded within the wet phase.

Earliest after 12 hours, respectively after hardening sweep the

exceeded sand off. Hereafter vacuum clean with an efficient

industrial vacuum cleaner.

MVB is no substitute to a moisture protection for

constructions according to standard.

Store MVB in cool, dry, frost-free conditions.

(Ideal storage temperature 18-20°C/60-68°F). Before working bring up to room temperature.

Storage life of 18 months (in closed sealed original packaging).

DISPOSAL

Excess material (A and B) should be mixed and allowed to cure. Cured product may be disposed without restriction.

Uncured materials should be stored in a suitable and sealed

container and may be disposed in accordance with provincial, State,

municipal, and /or Federal regulations.

GISCODE

RE 1 - epoxy resin product solvent free, sensitising.

CLEANING

Clean tools immediately after use with a solvent based cleaner.

Wear suitable personal protective equipment is necessary in any case. Please, find details on in the safety data sheet.

LIMITATIONS

Product should be used immediately after mixing.

Requires ICRI CSP 3 This product requires proper surface profile to

perform as expected. Substrate must be mechanically profiled (ASTM

4259-83), clean, sound, and dry.

Do not use product that has begun to cure.

Do not mix product longer than three minutes.

Over mixing will initiate the curing process prematurely.

Do not use in low-temps.

Do not use material that has crystalized.

Do not use over oil-based products.

If applied at low temperature, the product might not cure properly.

We strongly recommend performing tests prior using the product.

Overheating the product could also create an exothermic reaction.

TOOTHED TROWEL APPLICATION

Use a toothed trowel type TKB B2 to apply MVB as a

single layer.

Pay attention to apply an even and tight coat. Avoid imperfections.

Apply within 24 hours to provide adhesion for subsequent levelling

compound layers.

APPLICATION AS A BONDING AGENT ON NON-ABSORBENT SUBSTRATES

Single-layer application with roller is sufficient.

Subfloor should be thoroughly cleaned and afterwards abraded.

Apply MVB with a suitable tool, e.g. notched squeegee,

roller evenly to the clean and dry substrate.

WWW

.EPOXYCHEMTEC.

COM

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

/

MVB

Epoxy Moisture Mitigation Primer System

TECHNICAL DATA SHEET Section 03 01 37

EditionV.2.2 09/2022

LEGAL DISCLAIMER: All information provided by GLOBAL STONE CORP concerning GLOBAL STONE CORP products, including but not limited to, any recommendations and advice relating to the application and use of GLOBAL STONE CORP products, is given in

good faith based on GLOBAL STONE CORP current experience and knowledge of its products when properly stored, handled and applied under normal conditions in accordance with GLOBAL STONE CORP instructions.

In practice, the differences in materials, substrates, storage and handling conditions, actual site conditions and other factors outside of GLOBAL STONE CORP control are such that GLOBAL STONE CORP assumes no liability for the provision of such information, advice, recommendations, or instructions related to its products.

(The user of GLOBAL STONE CORP product(s) must test the

product(s) for suitability for the intended application and purpose before proceeding with the full application of the product(s)).

GLOBAL STONE CORP reserves the right to change the properties of

its products without notice. All sales of GLOBAL STONE CORP

product(s) are subject to its current terms and conditions of sale

which are available by calling TF [844] 829-1717, or via email at info@globalstoneindustries.com

EPD - Self-declaration

GLOBAL STONE CORP stands behind the quality of its products,

However, cannot guarantee results since GLOBAL STONE CORP has no control over outside operations, surface preparation, operating

conditions, and application procedures. Clients are solely responsible to test the products to determine if they perform as expected and/or as per their intended projects and/or use.

Contact Global Stone Corp for additional information regarding the limitations of this product.

GLOBAL STONE CORP declares that the product fulfills the criteria

for reactive resins based on epoxy resin, unfilled, solvent free with low

content of reactive diluent.

TECHNICAL

& SAFETY LITERATURE

Information on the safe handling of chemical products, as well as the essential physical, safety-related, toxicological, and ecological data can be found in the current safety data sheets (MSDS/SDS).

Observe all relevant regulations, e.g., the hazardous substances act. Further instructions and additional information can be found on the internet at www.globalstoneindustries.com . To acquire additional information, refer to the technical and safety literature, or contact your Global Stone Technical Representative: 786 601 2459, or via email at info@globalstoneindustries.com.

SAFETY

Consult MVB Safety Data Sheet.

Avoid contact with skin. Some individuals may be allergic to epoxy resin. Protective gloves, facial and ocular protection, proper ventilation, and clothing are recommended.

WARRANTY

- KEEP AWAY FROM CHILDREN – - FOR INDUSTRIAL USE ONLY -

COATINGS warrants this product to be free from manufacturing defects. The products are warranted for one year after date of application. Please refer to the GLOBAL STONE CORP Limited Material Warranty for additional information.

GLOBAL STONE CORP will replace at no charge the quantity of the Coating that GLOBAL STONE CORP determines has failed to perform, as the sole and exclusive remedy for any breach of this warranty and/or any other defect or failure of the coating. Proof of purchase is required. Cost of labor for application of any product specifically is excluded.

WWW

.EPOXYCHEMTEC.

COM

www.globalstoneindustries.com

WWW

+1 (786) 601-2459

+1 (305) 587-6243

REVISED VERSION V.1.5 : MAY 2023

4117 BOULEVARD INDUSTRIEL, LAVAL (QC) H7L 6G9 CANADA

COM

1 844.829.1717 • 450.629.1717

10810 SW 188th ST, Cutler Bay, FL 33157, US

white

BLACK

LIGHT GREY

MEDIUM GREY

LIGHT BEIGE

BEIGE

tan

GS 100

(3 Gallon of Kit Epoxy System)

PRE MIXED COLOR CHART